The fully automatic cartoning machine is a state-of-the-art packaging equipment that integrates several processes into one seamless operation.

Here's a breakdown of its capabilities and features:

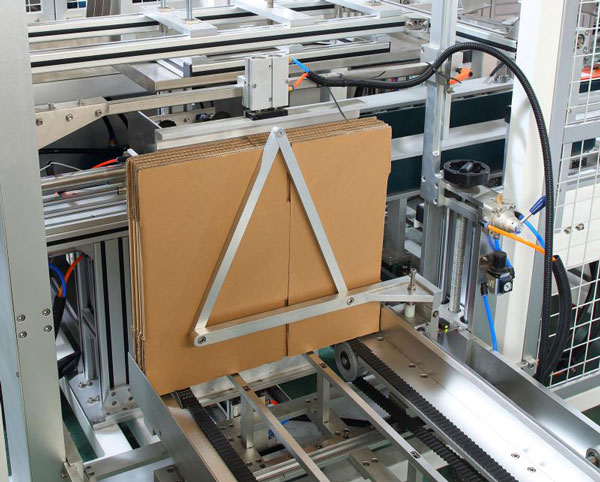

1. **Integrated Processes**: The machine is designed to perform a range of functions automatically, including opening cartons, stacking products, placing them into the cartons, and sealing the cartons.

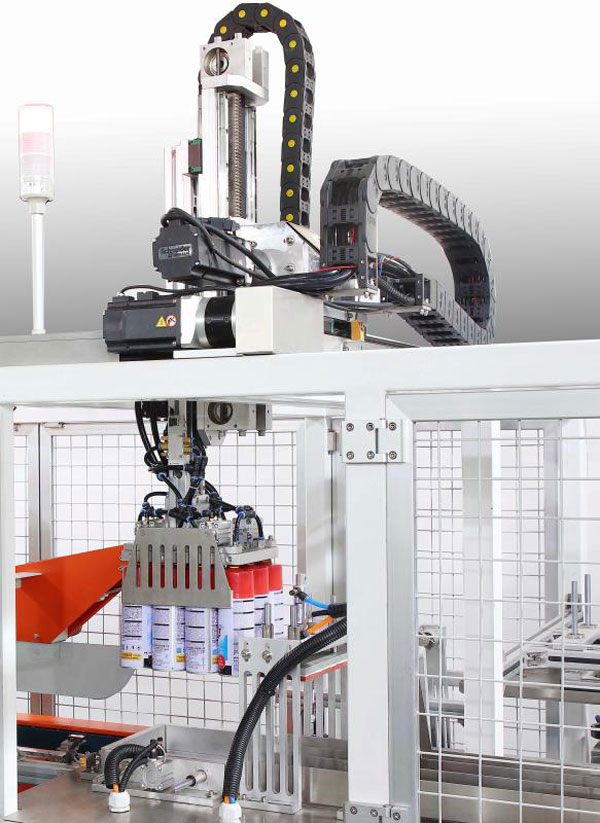

2. **Optional Robotic Arm**: It can be equipped with a robotic arm to further enhance its functionality and efficiency.

3. **Advanced Performance**: The machine's performance parameters meet international standards, indicating its high quality and reliability.

4. **Servo Control System**: Utilizing a full servo control system, the machine ensures precision and efficiency in its operations.

5. **Detection Features**: The machine is equipped with various detection features at different workstations:

- Carton shortage detection to ensure there's always a carton available for the next product.

- Product infeed detection to confirm the presence and correct positioning of the product.

- Stacking overload protection to prevent damage to the machine and the products in case of excessive force during stacking.

- Carton position detection to ensure accurate placement of the cartons.

6. **Full Monitoring and Control**: The machine offers full monitoring of the production process, with controls in place throughout the entire operation. This ensures that every step is carefully managed and any potential issues can be quickly identified and addressed.

This fully automatic cartoning machine represents a significant advancement in packaging technology, providing a high level of automation that can greatly increase the efficiency and quality of the packaging process. Its use of advanced control systems and comprehensive detection features makes it a reliable and effective solution for various industries.

Using high-end slide rails and Taiwan's Shangyin tank chain to ensure the stability and durability of the two-axis robot.

The horizontal placement and delivery of boxes makes it easier to place and deliver boxes, and can deliver up to 80 boxes at a time.

Made explosion-proof

Q1: How to choose the automatic case packing machine?

A1: please send the case size and picture,and product details,capacity request?

Q2: Can you support after-sales service?

A2: We provide lifetime after-sales service. We provide free Internet technical help, English technical manual, detailed operation video, and we can also provide engineers with on-site machine operation and machine maintenance training.

Q3:Why should we choose your company?

A3: We specialize in R&D, manufacturing and sales of various packaging equipment for more than 10 years and provide the best after-sales service.

Q4: How about warranty period for the machine?

A4: The warranty period is two year (nonhuman damage)

|

Production capacity: |

≤300(boxes/hour) |

|

Packing goods: |

Cartons,etc |

|

Power supply/power: |

AC380V/6.5KW |

|

Air pressure: |

0.6Mpa(6kg/c㎡) |

|

Air consumption: |

350L/min |

|

Machine dimensions: |

L4000*W2610*H2800 |

|

Machine weight: |

About 1200kg |

|

Applicable carton range: |

L500*W400*H600(Max) |

|

Stacking capacity of cartons: |

100pcs/hr(corrugated box) |

|

Carton material: |

General spcifcation corrugated paper |

|

Using tape: |

48mm or 60mm wide |

GET A QUOTE