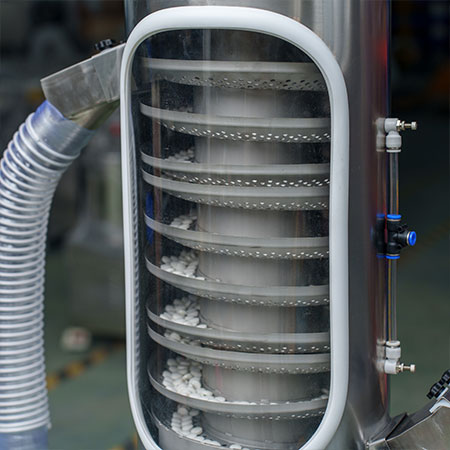

The tablet screening machine is a specialized equipment used for dust removal, edge trimming, surface polishing, and height elevation of tablets. The screening machine uses dust removal and vibration principles to remove excess powder while continuous vibration causes the tablets to rise. Additionally, the screening machine applies compressed air sweeping, centrifugal de-powdering, and roller edge trimming principles to remove powder attached to the surface of the tablets and edge fuzz, making the tablet surface clean and the edges neat.

Efficient Dust Removal and Polishing: The screening machine effectively removes powder from the surface of tablets and trims the edges, enhancing the glossiness of the tablets.

Automated Operation: The automated operation of the screening machine reduces manual intervention, improving production efficiency and ease of operation.

Strong Adaptability: The screening machine can be used in conjunction with various models of tablet presses and metal detectors, offering good adaptability and compatibility.

Tablet dedusters are necessary equipment for tablet production. lt uses to clean the dust on the tablet surface, polishing, making the tablet smooth and clean.

|

Model |

ZP-5A |

|

Capacity |

300000 pcs/h (Round tabletΦ5) |

|

Suitable tablet size |

Φ5-Φ25mm |

|

Power supply |

110-220V,50-60HZ |

|

Power |

150W |

|

Overall size |

570*470*1540mm |

|

Weight |

62kg |

GET A QUOTE