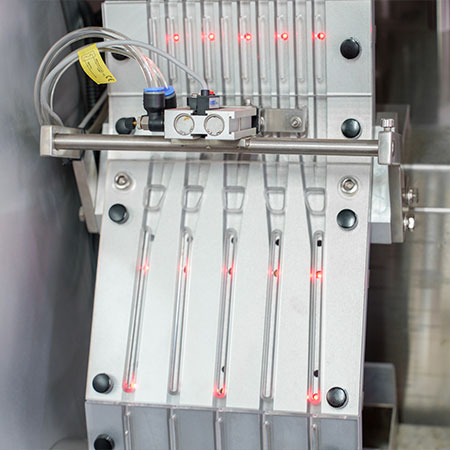

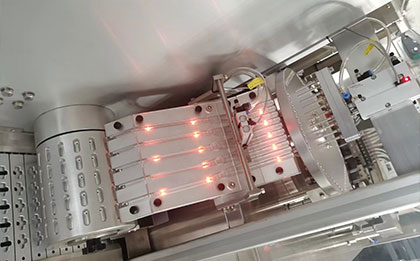

The self-developed multi-row rotary guiding mechanism provides the ability to handle capsules with high efficiency, but the capsule conveying speed is not fast enough to prevent poor guiding, wear and tear, and poor peeling of printed words.

|

Model No. |

NSF-600 |

NSF-1200 |

NSF-2000 |

|

Output |

600pcs/min |

1200pcs/min |

2000pcs/min |

|

Applicable capsule# |

00#~2# and safe capsules A~E |

00#~2# and safe capsules A~E |

00#~2# and safe capsules A~E |

|

Noisy |

≤75dBA |

≤75dBA |

≤75dBA |

|

Vacuum degree |

-0.02~-0.06 MPa |

-0.02~-0.06 MPa |

-0.02~-0.06 MPa |

|

water flow |

250L/h |

250L/h |

250L/h |

|

Inner diameter of water inlet pipe |

20mm |

20mm |

20mm |

|

Drain pipe inner diameter |

27mm |

27mm |

27mm |

|

Material |

Parts in direct contact with capsules and drugs are made of 304 and 316 high-quality stainless steel |

Parts in direct contact with capsules and drugs are made of 304 and 316 high-quality stainless steel |

Parts in direct contact with capsules and drugs are made of 304 and 316 high-quality stainless steel |

|

Power |

380v 3p,50hz,7.75kw |

380v 3p,50hz,7.75kw |

380v 3p,50hz,7.75kw |

GET A QUOTE