Liquid

Capsule Filling Sealing Machine

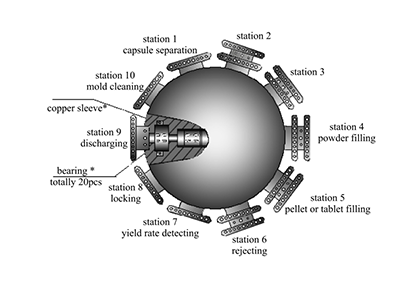

Liquid Capsule Filling and Sealing Machine is specifically designed to liquid and insoluble drugs or health care products that leave an unpleasant taste, odor or oxidizing discoloration. It is a fully automatic machine suits for oily liquid, solution, mixed suspensions or paste formulations. Compared to traditional hard capsules, liquid-filled capsules feature a wider adaptability, high transparency, high heat tolerance, moisture resistance, good sealing performance and tenacity.

-

□ Automated capsule processing

The automatic capsule filler can automatically complete the process of seeding capsule, separating, filling and rejecting waste, reducing manual operation.

-

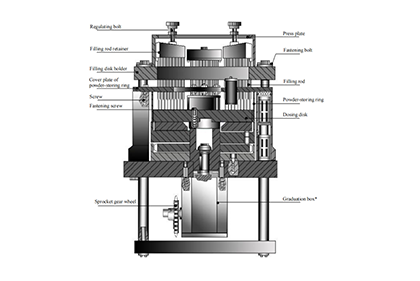

□ Precise drug filling system

Equipped with optimized metering system to ensure the accuracy and consistency of filled drugs.

-

□ Multiple capsule compatibility

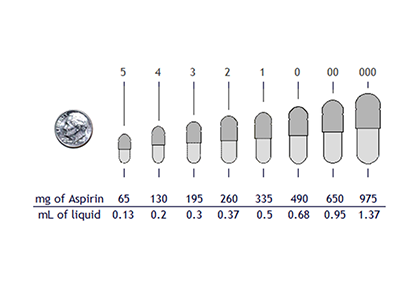

Capsule Filling Machine can be applied to different types of capsules, such as 0#, 1#, 2#, 3#, 4#, 5#, etc.

- □ Defect detection and rejection

-

□ GMP-compliant design

Designed for easy cleaning and maintenance, in line with GMP (Good Manufacturing Practices) standards.