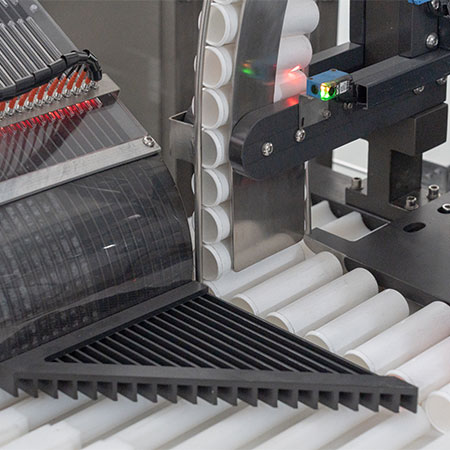

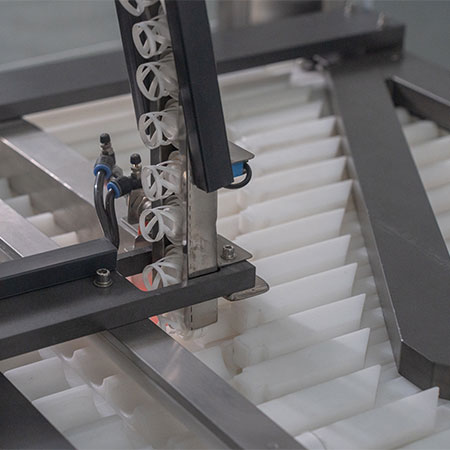

Effervescent Tablets Tube Filling Machine is designed for precision and efficiency, with automatic controls and GMP-compliant stainless steel construction. It uses sensors for accurate tablet counting and has an alarm system for safety. The machine offers both semi-automatic and fully automatic modes, ensuring gentle handling of tablets and can be equipped with nitrogen flushing to protect the product. Versatile for various packaging materials, it's ideal for pharmaceutical, food, and healthcare applications.

The High Speed Effervescent Tablets Tube Filling Machine is an efficient and advanced solution for high-volume pharmaceutical production.

It boasts a rapid filling speed of up to 120 tubes per minute, ensuring quick processing for large-scale operations. With PLC control, this machine offers precise monitoring and complies with stringent industry standards. Its gentle handling of tablets and nitrogen flushing feature protect the product from damage and moisture, respectively. The machine's compact design and quick mold change capability allow for flexibility and ease of use. It also features intelligent controls for simplified operation and can be integrated with labeling machines for streamlined production. Ideal for maintaining product quality and integrity at high speeds, this filling machine is a top choice for the pharmaceutical industry.

|

Model |

UR-120 |

|

Loading qty |

10-20pcs/tube |

|

Tube length |

60mm-200mm |

|

Tablet diameter |

16mm-33mm |

|

Tablet thickness |

3mm-12mm |

|

Capacity |

80-120tubes/min |

|

Dimension(L X W X H) |

2500mm*1600mm*1700mm |

|

Weight |

600kg |

GET A QUOTE