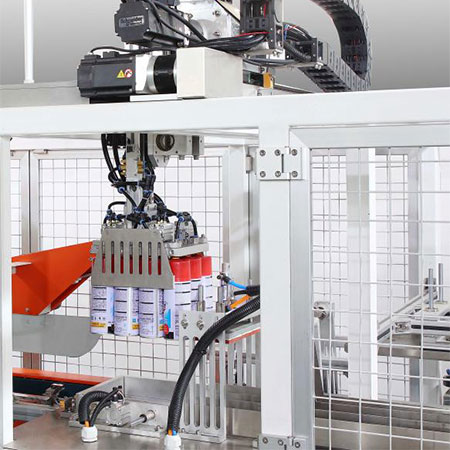

The gripping type case packing machine is an automated machine used for boxing and packaging products from the production line into boxes for storage, transportation, and sales. This type of packing machine can quickly and accurately place products into packaging boxes or crates, improving production efficiency and reducing the time and cost of manual operations. It consists of a system with robotic arms, conveyor belts, control systems, and more, to grasp products from the production line and place them into the appropriate packaging containers.

The gripping type case packing machine is an automated equipment that uses mechanical arms or gripping devices to pick up products directly from the production line and place them into packaging boxes. This type of machine is particularly suitable for items that are irregularly shaped or heavy, as it can increase the speed and efficiency of boxing while reducing manual labor. Gripping type case packing machines are widely used in industries such as food, beverages, chemicals, and electronic products due to their flexibility and adaptability.

|

Packing type |

Grab way |

|

Packing capacity |

80-500 cases/hr |

|

Applicable case range |

L:max600-min200 W:max500-min150 H:max350-min100 |

|

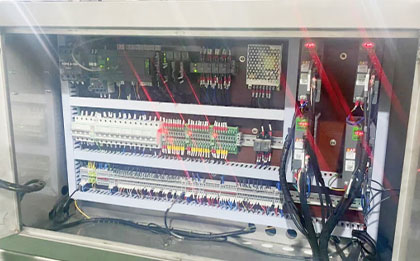

Power supply |

220v,1.4kw |

|

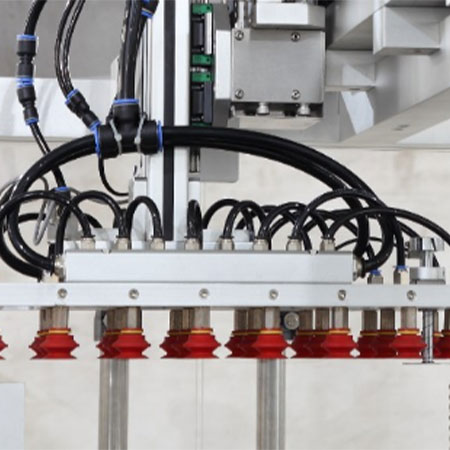

Air pressure |

0.5-0.6Mpa |

|

Air consumption |

350L/min |

|

Dimension |

5200*2300*1900 |

|

Weight |

1200kg |

GET A QUOTE