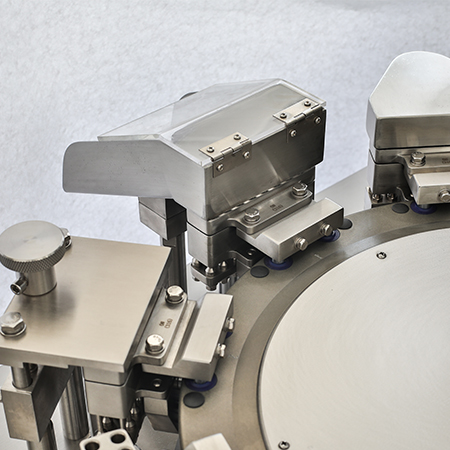

The automatic Capsule Polishing Machine is a special polishing equipment for capsules. It can remove dust on the surface of capsules, improve the surface quality of capsules, and automatically remove unqualified capsules.

Capsule polishing machines are vital in pharmaceutical manufacturing, enhancing the appearance of gelatin capsules before packaging. These machines feature conveyor belts that move capsules through polishing chambers. Here, they undergo thorough cleaning to remove imperfections, dust, and static. Methods like rotating brushes and air jets ensure capsules achieve a smooth, glossy finish without damage.

| Applicable Product | Oil Based Solution And Suspension |

| Capsule Size | 00# – 2# |

| Capacity | 18,000 capsules/h |

| Motor Power (Plunger Pump) | 3.1kw+2.2kw (Dust Collector) |

| Power Supply | AC 220V/380V 50/60Hz 3 Phase |

| Noise | ≤75dBA |

| Vacuum Degree | -0.02~-0.06 MPa |

| Dimension | 870*1090*2100mm |

| Weight | 850kg |

| Applicable Product | Oil Based Solution And Suspension |

| Capsule Size | 00# – 2# |

| Capacity | 36,000 capsules/h |

| Motor Power (Plunger Pump) | 3.1kw+2.2kw (Dust Collector) |

| Power Supply | AC 220V/380V 50/60Hz 3 Phase |

| Noise | ≤75dBA |

| Vacuum Degree | -0.02~-0.06 MPa |

| Dimension | 870*1090*2100mm |

| Weight | 850kg |

| Capacity | 18,000 capsules/h |

| Motor Power | 3.6kw |

| Power Supply | AC 220V/380V 50/60Hz 3 Phase |

| Air Compression | 6m³/h |

| Relative Humidity | 40%~55% |

| Temperature | 22℃~28℃ |

| Dimension | 2460*920*1900mm |

| Weight | 1000kg |

| Capacity | 36,000 capsules/h |

| Motor Power | 3.6kw |

| Power Supply | AC 220V/380V 50/60Hz 3 Phase |

| Air Compression | 6m³/h |

| Relative Humidity | 40%~55% |

| Temperature | 22℃~28℃ |

| Dimension | 2460*920*1900mm |

| Weight | 1000kg |

Welcome to our comprehensive guide to capsule fillers, where you'll delve into the intricate details of modern pharmaceutical equipment.

From understanding the principles behind capsule filling to exploring the latest advances in technology, Yulin is always with you!

GET A QUOTE