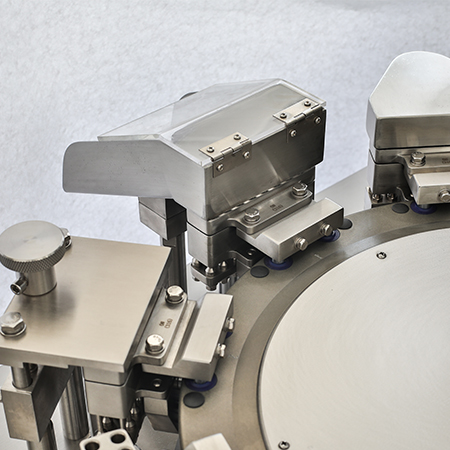

The Capsule Automatic Filling Machine has a simple and intuitive operation interface, is easy to operate, and is equipped with a high-precision metering system, suitable for capsule shells of various sizes and types.

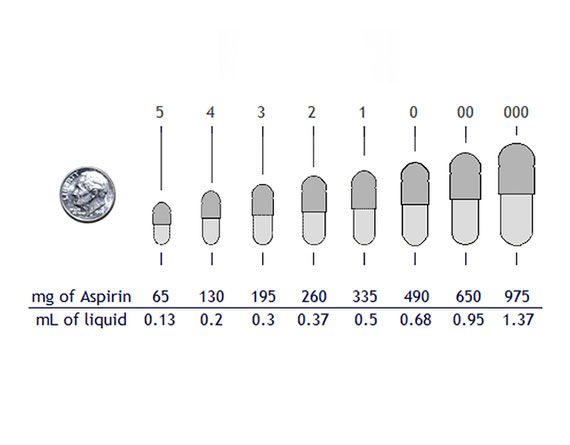

The Automatic Capsule Filling machine according to client requests for varying capacities, specializing in capsule sizes ranging from 000# to 5#.

Your order is guaranteed to ship within seven days.

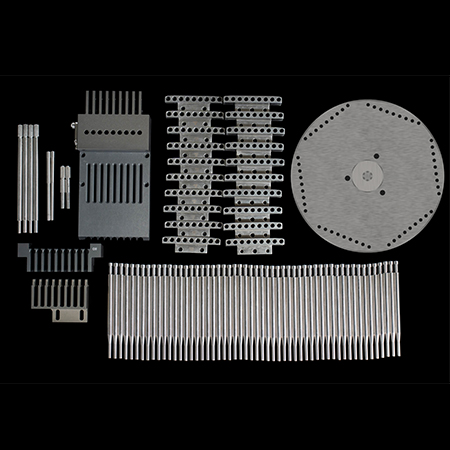

The Automatic Capsule Filling machine is utilized for filling both powder and pellets. Our product line features two primary types: the S series, designed as a compact laboratory model that is easily portable, catering to small-scale manufacturers and laboratories; and the C series, our standard model available in various output capacities to suit diverse manufacturing requirements. With interchangeable capsule molds, it facilitates filling capsules of different sizes on a single machine. Moreover, it supports both powder and pellet filling when equipped with respective feeders, offering versatile functionality within pharmaceutical and manufacturing settings.

| Model | NJP200S | NJP400S |

| Output | 12,000 capsules/h | 24,000 capsules/h |

| Number of Die Holes | 2 | 3 |

| Application | 00#-4# | |

| Total Power | 3kW | |

| Dimension | 700*570*1650mm | |

| Weight | 350kg | |

| Capacity | 12,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 3kW |

| Quantity of Mould Bores | 2pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 610*670*1800mm |

| Weight | 600kg |

| Capacity | 24,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 3kW |

| Quantity of Mould Bores | 3pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 700*900*1800mm |

| Weight | 700kg |

| Capacity | 48,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 4kW |

| Quantity of Mould Bores | 6pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 730*950*1800mm |

| Weight | 800kg |

| Capacity | 72,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 5kW |

| Quantity of Mould Bores | 9pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 800*1000*1800mm |

| Weight | 900kg |

| Capacity | 120,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 8kW |

| Quantity of Mould Bores | 18pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 1000*1300*1900mm |

| Weight | 1000kg |

| Capacity | 210,000 capsules/h |

| Application | 000# to 5# |

| Power Supply | 220/380V 50Hz 3Phase |

| Power Consume | 10.5kW |

| Quantity of Mould Bores | 25pcs |

| Noise Standard | ﹤75dB(A) |

| Dimension | 1170*1560*2000mm |

| Weight | 2200kg |

Welcome to our comprehensive guide to capsule fillers, where you'll delve into the intricate details of modern pharmaceutical equipment.

From understanding the principles behind capsule filling to exploring the latest advances in technology, Yulin is always with you!

GET A QUOTE