Urmachine is a China manufacturing company of many types of automatic blister packing machines.

The blister packaging machine is an automated packaging equipment widely used in industries such as pharmaceuticals, food, and electronics. It packages solid products like tablets, capsules, candies, and batteries by forming individual plastic cavities or blisters, typically made from PVC or PET materials. Blister packaging not only protects products from moisture, light, and air, extending their shelf life, but also provides intuitive checks for product quality and authenticity, helping to improve patient compliance with medication.

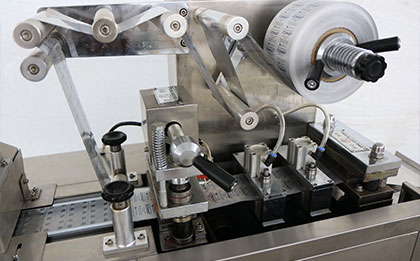

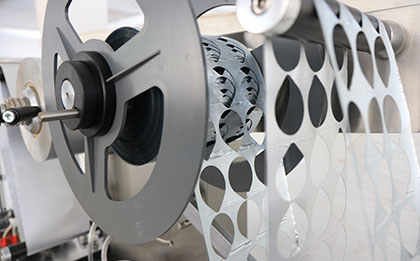

The main workflow of the blister packaging machine includes material preparation, blister forming, product filling, blister sealing, quality control, printing and marking, and packaging storage. In the pharmaceutical industry, this packaging method is particularly important as it ensures the integrity and safety of the medication, complies with strict regulatory standards, and reduces the possibility of human error.

Many models of our automatic blister packing machines meet most of the blister packaging products on the market. The DPP88 model is a model suitable for small-scale manufacturers. DPP260 model adopts the mold positioning design, which is convenient for customers to replace the mold and reduce the debugging time and material cost. DPPA series blister packing machines are aluminum-plastic packaging models with high-cost performance. DPPE series models have two functions blister packing of ALU-PVC and ALU-ALU by replacing the mold. DPPF series models are suitable for aluminum-plastic, aluminum-aluminum, and aluminum-plastic-aluminum blister packaging. And our automatic blister packing machine can also customize according to the customer's material.

|

Model |

DPP420 |

|

Blanking frequency |

10-25times/min |

|

Max. forming area and depth |

390×180×26 mm |

|

Range of travel |

40-180mm |

|

Packaging material request |

PVC-0.15-0.5×420mm PTP ALU:0.05-0.1×420mm |

|

Power |

380V/220V 50Hz 22kw |

|

Air pressure |

0.4-0.6Mpa |

|

Mould cooling |

Tap water or circulating water |

|

Dimension(L X W X H) |

6000*950*2000mm |

|

Weight |

2000kg |

GET A QUOTE